This is why you should always disassemble cheap Chinese charging accessories before use

I buy a lot of stuff from Chinese sellers on eBay and various Chinese sites like DealExtreme. It’s a game of luck; sometimes you strike gold and get epic cases for both your devices for less than $2/each, or an iPad mini dock for $10, but other times you end up with a pile of junk on your desk. Bad quality isn’t too critical for a case, since it only means you won’t use it, but for anything charging related it might actually damage your device. I always disassemble any charging related accessory from such places before use, and today that paid off.

There are good charging products out there on these sites. My review of the $10 iPad mini dock showed that, and I also mentioned the importance of checking the internal components before use in such cases. You really shouldn’t skimp out on doing that, even between different units of the same product. Today, I received another cheap dock- this time a white $11.50 dock– and when I opened it up to see inside, proof that I’m not paranoid was glaring back at me.

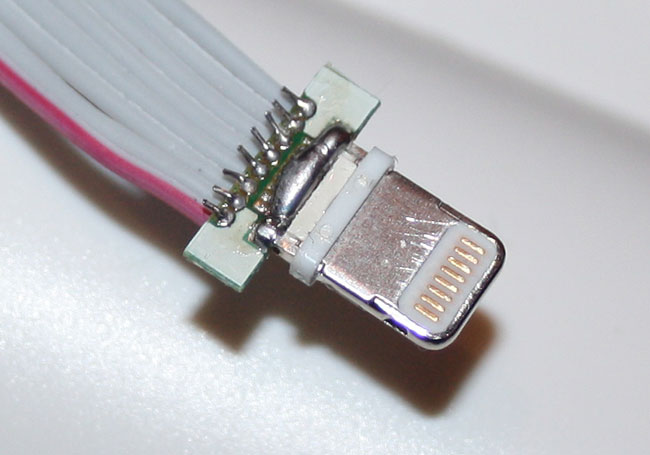

There, inside the dock, was a giant blob of solder that was splattered across all the pins of the Lightning connector’s internal end. It covers every single one of the pins, short circuiting the entire connector. There is another set of pins on the back that aren’t covered, which means that either this is an actual mistake, or these short circuited pins aren’t actually connected to anything. I dare not take the chance that it’s the former, and don’t have a multimeter to test right now.

Another issue with this particular dock is that the breakout board (the tiny PCB that takes the small pins coming from the Lightning connector and spreads them out for easier access) is very small compared to the other dock I reviewed. I cannot actually tell if the soldering points for the ribbon cable are touching or not, but they appear to be, which means there’s a second potential short circuit point on one single tiny PCB. The other end- where you would connect your own cable- is better spaced out and properly soldered, but that doesn’t help much when one end is so bad.

It’s easy to test for actual short circuits if you have the equipment, but most people don’t. The screwdriver needed to take a dock like this apart, however, is not as rare. It’s easy to spot bad soldering points, and if you see those, stay away. If soldering points are too close for you to see if they’re touching or not, you shouldn’t use them to begin with.

August update: I’ve gotten a lot of comments on this, and many of them complain that the giant blob of solder is just ground, even after I tested the thing to be short circuited. As such, I did another test of the thing (since I still have it in my box of random parts), to find out exactly what’s wrong with it. It comes down to this: The commenters were right about the blob, I was right about not plugging it into something. The connector’s business end pins are short circuited, but the short circuit is located in the breakout board where it connects to the ribbon cable, not the blob of solder like I first thought when I tested it and found the short. So in a nutshell, I was right to be cautious, though wrong about what part of the connector was bad. My apologies to anyone who for some reason took that personally. The bottom line is that I will continue to eer on the side of caution when I see something that looks sketchy, and while I might be wrong from time to time, I’d rather be wrong about it being unsafe than being wrong about it being safe.

You should really get that multimeter, before you write this article , because it raises more questions than answers. So please get one, and confirm for us, if there is any short circuit.

I can borrow you one of many I use, just to sleep peacefully.

Thanks.

I could make something that would work like a multimeter if I really needed to, but I think that’s redundant. The internal PCB here has two potential short circuits, and one of them is a design flaw (distance between solder points) that means I wouldn’t use this dock no matter if there’s an actual short circuit or not. Also, like I point out, you need to take apart every single unit, as there can just as well be differences from one production batch to another, or one unit to another.

You should be able to tell just from looking at the PCB that something is safe, and if you can’t, you frankly shouldn’t trust the long term longevity of it no matter what the multimeter would have told you. The point of this article was to show why it’s important to check, and what to look out for, not determine whether or not the specific unit I received is faulty, as that would really only be useful to me, not even someone receiving the same dock on the same day as me.

That is a Great find.

But I do not think it is reasonable to expect anyone to take apart and inspect their purchase. It is much easier to scour tech sites and see the lessons someone else learned.

I ignore any offering that comes in at less than 2/3 of the price I expected to pay. Especially from China.

My friend bought a cheap accessory pack for their kids iPod touches. One kid plugged in their ipodtouch and it popped and died. Being kids, the other one plugged in theirs to see what happened. The second one popped too. Now there are no iproducts in their house. Good riddance.

Peace

Good point; that’s a little scary!

I bought my sister a Lightning charger from FastTech.com (http://www.fasttech.com/) and they seem a little more reputable than DX. 45-day refund period, 6-month return period. I took the chance, haha, but now I’ll be sure and check out the cables.

I do a lot of electrical assembly by hand, and everything in the picture looks completely a-o-k to me. Test it with a multimeter if you must but I wouldn’t even bother if I was you. There is literally nothing that could be wrong with the soldering that would threaten your phone. If it’s shorted, the low-voltage half of the transformer will quietly “burn out” which will probably consist of some goop bubbling out of one or two capacitors and a foul odor.

Anyway, test-plugging something like a cable assembly is so fast and easy that there’s literally no price point where a company will decide not to. Especially with power connects; traders often don’t return to a manufacturer who exposed them to liability, real or imagined.

I just updated the article since I did indeed test it in the end. I was right, and every single pin is short-circuited due to that blob of goo. On top of that, you have a comment on this post that tells of a real world example of such accessories killing off a device, so I’m sorry, but you’re quite far off here.

Really good write up mate, I’ve tinkered with electronics for a good few years and just looking at that image tells me that charging device is going to be dodgy.

Obviously a DMM is going to tell you where the short(s) are, but there’s no way I’d stick that into my phone to charge it up!

One time Western Digital released a USB drive with a defective USB cable. The cable was wired incorrectly and was frying the USB ports on everybody’s computers.

The funny thing is, people didn’t know the cable was bad, they just thought their computer wasn’t seeing the drive for whatever reason, so when the drive didn’t work, they would try it on a different computer to see if the drive would work there, but those ports would then fry too.

Needless to say, Western Digital had to pay to fix allot of computers. But there are allot of computers they didn’t have to pay for, because the consumers never know it was Western Digital’s USB cable that broke their computer.

Yet you still buy chinese, where they slave for 2.50$ a day, and wonder why you get crap.

I agree though, always double check where your product originated from. Even American sellers just buy bulk China and sell to u. So do research.

I have to wonder if you are actually getting a bargain if you are buying multiples of accessories and picking through to find one that actually works. Wouldn’t it be better to just buy a high quality product from a known, reputable manufacturer with proper quality controls in place rather than fish for a cheaper product that will actually work?

Joe,

When I find an American electronic manufacture that makes it’s products in America and does not charge $30.00 for what I can get from china for $5.00, I will start to feel guilty. Besides, most if not all tablets are made in China or a EasternAsia country that pays the small wages that you mentioned. I have very few choices when it comes to “made in America”. Perhaps maybe when unions, EPA regulations, energy costs, corporate taxes, etc. Stop forcing manufacturing and jobs to be outsourced to these countries, I will be able to by American again. Until that happens you bet I will pay a unmarked up price for the same product that has an American logo but is made in china but costs double or more.

This is why i buy all my cables from monoprice. they might be as cheap as some of these chinese knockoffs, but they dont sell crap, and will take responsibility for any defective things you get.

wow dude

you sure that isn’t just the grounding?

I know several people that swear by Monoprice and i’ve used them before for odds and ends. My question, though, is the part about “will take responsibility for any defective things you get”… so does that mean if my device gets destroyed they’ll replace it? Curious.

Isn’t that the earth? All the pins that are used for shielding are joined together like that.

This is perfectly normal! These are ground pins and they are supposed to be connected together.

Please read the update. I’m well aware of how grounding works, but that’s hardly relevant when the “grounding blob” flows over where it doesn’t belong and has been proven to actually short circuit the connector.

This is perfectly normal! These are the negative pins and they are supposed to be connected together.